The Critical Path Method, also known as CPM, was developed as a way to plan and schedule plant maintenance and commercial construction projects by utilizing computers. Successful applications of CPM methodologies led to the extensive use of CPM on government & industry projects.

So what exactly is CPM for commercial construction?

This may also be referred to critical path scheduling, mainly because it calculates the minimum time needed to complete a construction project. This incudes the possible start and end times for the different activities that arise during the entire process. The concept of CPM is nowadays shown by computer programs that perform the necessary calculations without needing to reference a graph.

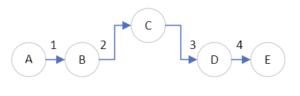

Firstly, a coding system must be established to identify each construction job required to complete the entire project; That must be accompanied by the length of time needed to accomplish the job, and its immediate prerequisite tasks. Specific jobs are posted to a graph (represented by a circle) with their specific coding details. Next, arrows are used to connect the circles indicating the next item in sequence. The full graph is what is known as a “Project Network.”

By creating this Project Network, it allows CPM to (a) create a schedule for the whole team during the project and (b) establishing a basis for tracking the project schedule performance.

The purpose of Critical Path Method (CPM)?

The term “Critical Path” represents the sequence of precursor activities that will take the longest time to finish. The total length is the compilation of all activities’ duration along the path. The whole of the critical path corresponds to the minimum time needed to complete a project. Any delays would signify the need for additional time to complete the construction project.

It is quite common to have more than one critical path during the life of the construction project. A project may be delayed by setting back construction activities along any of these paths. Scheduling assumes that a project has been split into activities of certain fixed durations as well as precise precursory relationships. A precursor or predecessor relationship indicates that one construction activity must come before another activity in the schedule.

What are the possible benefits of the Critical Path Method?

A general practice with construction project planners and coordinators are to introduce a resource constraint by a precedence relation. In construction terms, this would be a restriction on the options available to the project manager. A resource constraint is caused by the limited availability in the terms of equipment, material, space, or labor.

If two separate activities in the project require the same piece of equipment, it may be that one activity will precede the other. This secures that the two activities utilizing the same set of resources will not be scheduled during the same time frame.

CPM helps to identify the most important tasks that require the most attention. If you know which tasks are on the critical path, this can help you prioritize. Nonetheless, if tasks take more time than you expected, the entire project will face the consequences of delays.

CPM helps you curb time overruns and accelerate accurate delivery times. After analysis of your critical path scheduling, you will have an overview of which task durations that may be reduced, ones that need to keep their current time frame, and which may be modified.

CPM makes it easy to track your progress in your project by comparing actual vs. planned progress.

Find out how Modern can help you with your construction needs! Click HERE to request more information!

Modern Construction & Facilities Maintenance Services is well-positioned to help our clients with any renovations, professional design, space repurposing, construction, interior refreshes, or maintenance issues for our healthcare clients. Reach out to us 24/7/365 and see how we make facility maintenance and construction easy!

www.modernconstructionsvc.com

704-765-9937

Modern Construction & Facilities Maintenance Services

5900 Harris Technology Blvd, Suite D

Charlotte, NC 2869